An Authoritative List of the Best Dust Collectors Manufacturers Available

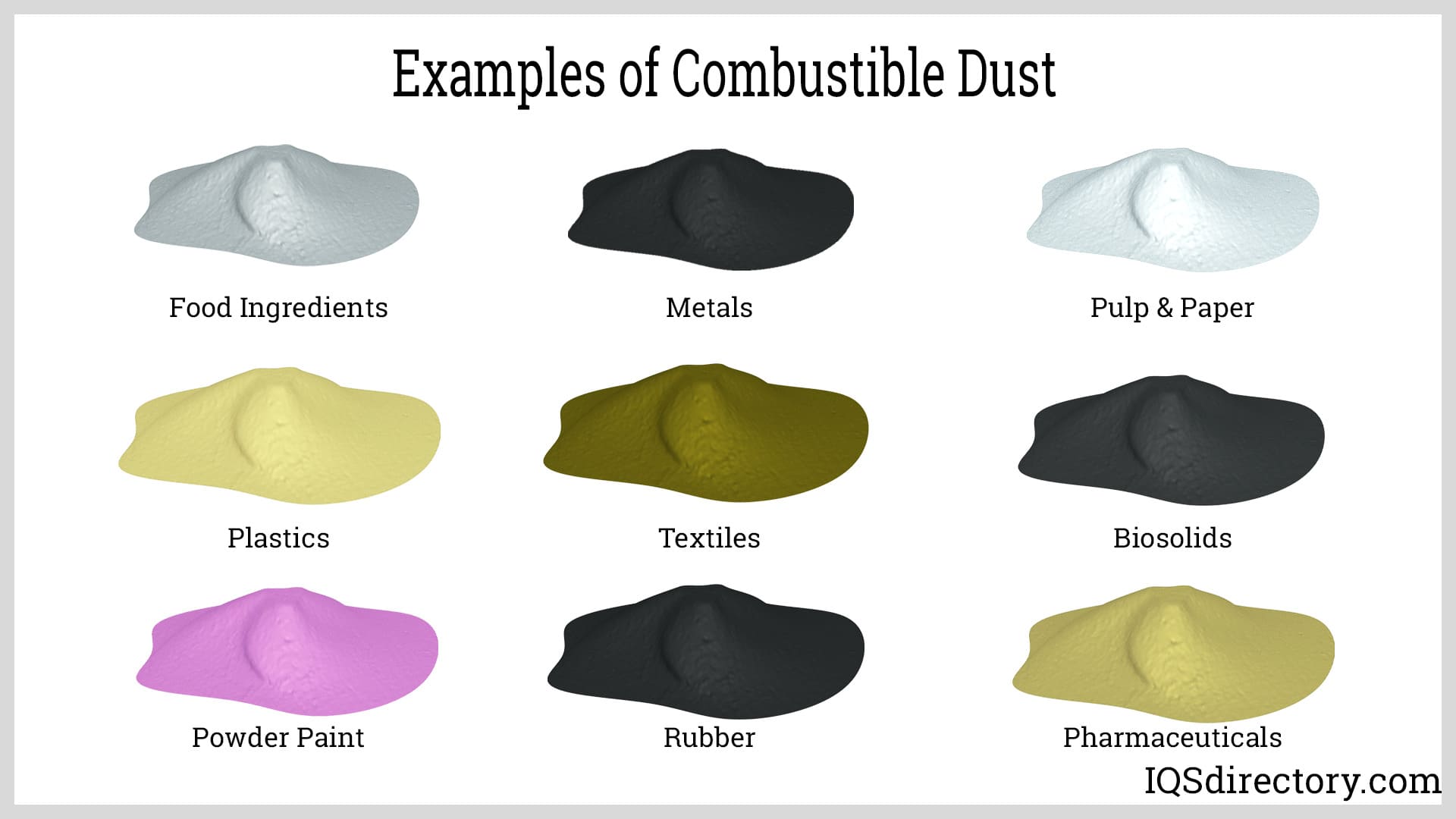

Many manufacturing processes release particles which are hazardous to both worker and equipment health. The responsibility for capturing and removing these particles lies with dust collectors. To accomplish this task, dust collection equipment traps harmful particles after drawing in contaminated air through a filter or separators. Clean air is then released either back into the work area or into the atmosphere. Effective dust collection can increase equipment lifespan and worker safety. There are many different types of dust collectors that can be found in an array of industries such as coal handling, mining, chemical processing, cement fabrication, pharmaceutical, woodworking, recycling and agricultural. Different kinds of dust collectors include jet dust collectors, baghouses, wet dust collectors, cartridge collectors, downdraft tables and portable dust collectors.

Baghouses are the most common design of dust collector used today due to their cost-effective design. Typically constructed from either glass fibers or fabric, baghouses draw contaminated air through ducts to a hopper-shaped baghouse. Wet dust collectors, on the other hand, use water to soak dust-filled gas streams. The wet dust particles are then separated through varying degrees of pressure drops. Cartridge collectors rely on compact filters with a far greater area than bags to separate hazardous particles from air streams. This lowers resistance and frequency of cleaning, while increasing airflow. Downdraft tables are actually a type of workbench designed to draw dust and fumes away from a worker’s breathing zone by utilizing perforated tabletops and back walls.

Not all dust collectors depend on filters to operate. For example, cyclone dust collectors and baffle chambers rely primarily on gravity and inertia to separate harmful particles from the air. This works because most particles are heavier than air particles. Once thrown against the wall of a collector or hopper, the particles will sink to the bottom where they are collected. Baffle chambers consist of a series of barriers that force the flow of air to change direction. These sudden changes in flow reduce the inertia of heavier particles, taking away suspension.

Larger facilities may utilize a combination of different dust collectors to create a fully effective dust collection system. A system may involve overhead ductwork, baghouses and inertial separators. Some dust collectors are even hooked up directly to machinery. They use a motor to act as a type of suction device to remove dust and hazardous particles from equipment during operations. This is very imperative for woodworking applications where sawdust may obstruct visibility and even slow machinery. Smaller, cleaner and more effective dust collectors are constantly being developed to increase worker safety and environmental health.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

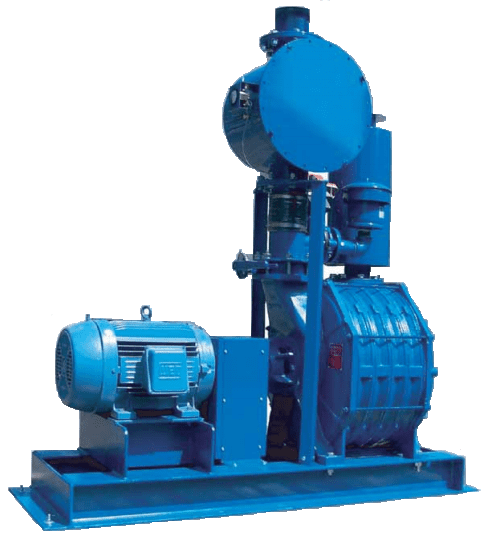

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services