Cyclone dust collectors are a form of inertial separator that uses centrifugal force to extract particles from a gas stream. Air is cleansed by cyclonic action generated inside the cyclone collection chamber. Read More…

Scientific Dust Collectors (SDC) began in 1981 when our first patent for improving filter cleaning was issued. Since then, SDC has been issued a number of additional related patents for improvements in dust collector cleaning technologies including our patented nozzle-based cleaning system which is superior to other collectors. Combined with our High Side Inlets, Wide Filter Spacing, and Inlet...

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our dust collector systems. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

At Coral USA Innovative Air Solutions, we are committed to delivering high-performance dust collection systems that enhance workplace safety, improve air quality, and ensure compliance with industry regulations. With extensive experience in air filtration and dust control, we design and manufacture advanced dust collectors that effectively capture and remove airborne contaminants, providing...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. Eliminating airborne contamination in the workspace can lead to better employee performance and a lower rate of absenteeism.

More Cyclone Dust Collector Manufacturers

Cyclone Dust Collectors: Industrial Air Filtration Solutions for Efficient Dust Removal

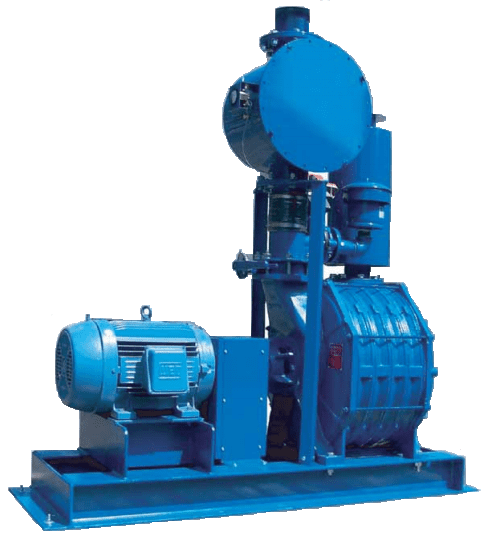

Cyclone dust collectors are essential components in modern industrial air filtration and dust control systems. They utilize a high-velocity circular airflow—resembling a vortex—to separate and capture dust particles, debris, and particulate matter from air streams. As dust particles are drawn into the cyclone chamber, centrifugal force pushes them against the cyclone wall. The dust then slides to the bottom of the hopper for collection, enabling efficient removal of both heavy and fine particulates from the working environment. Cyclone dust collection systems are especially effective at eliminating large, abrasive particles and are frequently used as pre-cleaners before baghouses or other downstream filtration equipment in a wide range of industrial applications.

Industrial Applications of Cyclone Dust Collectors

Wondering which industries benefit most from cyclone dust collectors? These systems are a trusted solution across sectors such as woodworking, pulp and paper, shot blasting, steel mills, grain processing, agriculture, recycling plants, cement manufacturing, and mining. Cyclones are ideal for environments that generate substantial amounts of coarse particulate or bulk dust—especially where particles are larger than 20 microns. They are highly regarded as mechanical separators that employ centrifugal force to remove airborne dust particles efficiently, protecting downstream equipment and improving overall air quality in industrial facilities.

Key Use Cases and Buyer Intent

- Woodworking Shops: Remove sawdust, wood chips, and shavings to maintain clean air and equipment longevity.

- Metalworking and Foundries: Capture abrasive metal dust, shot blast residue, and slag.

- Grain and Agricultural Facilities: Control grain dust, husks, and processing debris for improved safety and compliance with OSHA and NFPA regulations.

- Recycling Plants: Separate bulk plastics, glass, and paper dust before further filtration or material recovery processes.

- Cement, Concrete, and Mining Operations: Remove silica, mineral dust, and aggregate particles to protect worker health and downstream filtration systems.

How Cyclone Dust Collectors Work: The Science Behind the System

Curious about the working principle of cyclone dust collectors? Cyclone systems are typically installed upstream of dust filters and positioned near critical equipment like vacuum pumps or conveyors. As contaminated air is drawn into the cyclone dust collector’s chamber, it accelerates into a rapid, spiral motion. This “cyclonic action” propels heavier particles and dust toward the outer wall, using centrifugal force to separate particulate matter from the air stream. The cleaned air then exits through the top outlet or is routed to additional filtration stages, such as baghouse or cartridge dust collectors, for removal of finer particles.

The separated dust and debris travel down the cyclone chamber wall, slowing due to friction, and ultimately fall into a collection hopper or bin below. In high-dust, high-volume environments, this pre-filtering step prevents excessive loading and wear on more sensitive downstream dust collection equipment.

Advantages of Cyclonic Filtration Technology

- Handles high dust concentrations and large particulate sizes with ease.

- Protects sensitive downstream filters by reducing dust loading and abrasion.

- Requires no moving parts—minimizing maintenance and maximizing system reliability.

- Versatile for a wide variety of industrial dust types, including wood, metal, mineral, grain, and plastic particulates.

- Improves air quality, supporting compliance with environmental and occupational health regulations.

Choosing the Right Cyclone Dust Collection System: Key Considerations

Are you evaluating which cyclone dust collector is best for your facility? The right choice depends on several critical factors, including airflow requirements, particulate characteristics, system footprint, and integration with other dust control technologies. Here’s what to consider when selecting an industrial cyclone dust collector:

- Dust control system requirements: Assess the total airflow (CFM) required to capture and transport airborne particulates. This depends on the size of your facility, the particulate loading, and the types of materials handled. A facility-wide dust management assessment can help determine whether a standalone cyclone or a multi-stage system is needed.

- Particle size and composition: What size are the particulates to be collected? Cyclones excel at removing larger particles (generally above 10–20 microns), while finer dust may require subsequent filtration through baghouses or cartridge collectors. Assessing your dust’s physical and chemical properties ensures optimal performance and regulatory compliance.

- System footprint and installation: Space constraints, building layout, and headroom availability affect system selection. Standalone cyclone dust collectors are often compact and cost-effective, but when paired with baghouse or cartridge collectors, additional floor space and discharging points are required.

- Pre-filtering and multi-stage filtration: For applications with a mix of coarse and fine particles, cyclones make excellent pre-filters—reducing dust burden on HEPA filters, baghouses, or cartridge systems and extending their lifecycle.

- Air recirculation vs. direct exhaust: Will filtered air be recirculated into the workspace or exhausted outdoors? Local air quality standards and energy efficiency goals may influence your design.

- Continuous vs. intermittent dust generation: Consider whether dust is produced constantly or only during specific processes, as this impacts system sizing, automation options, and maintenance intervals.

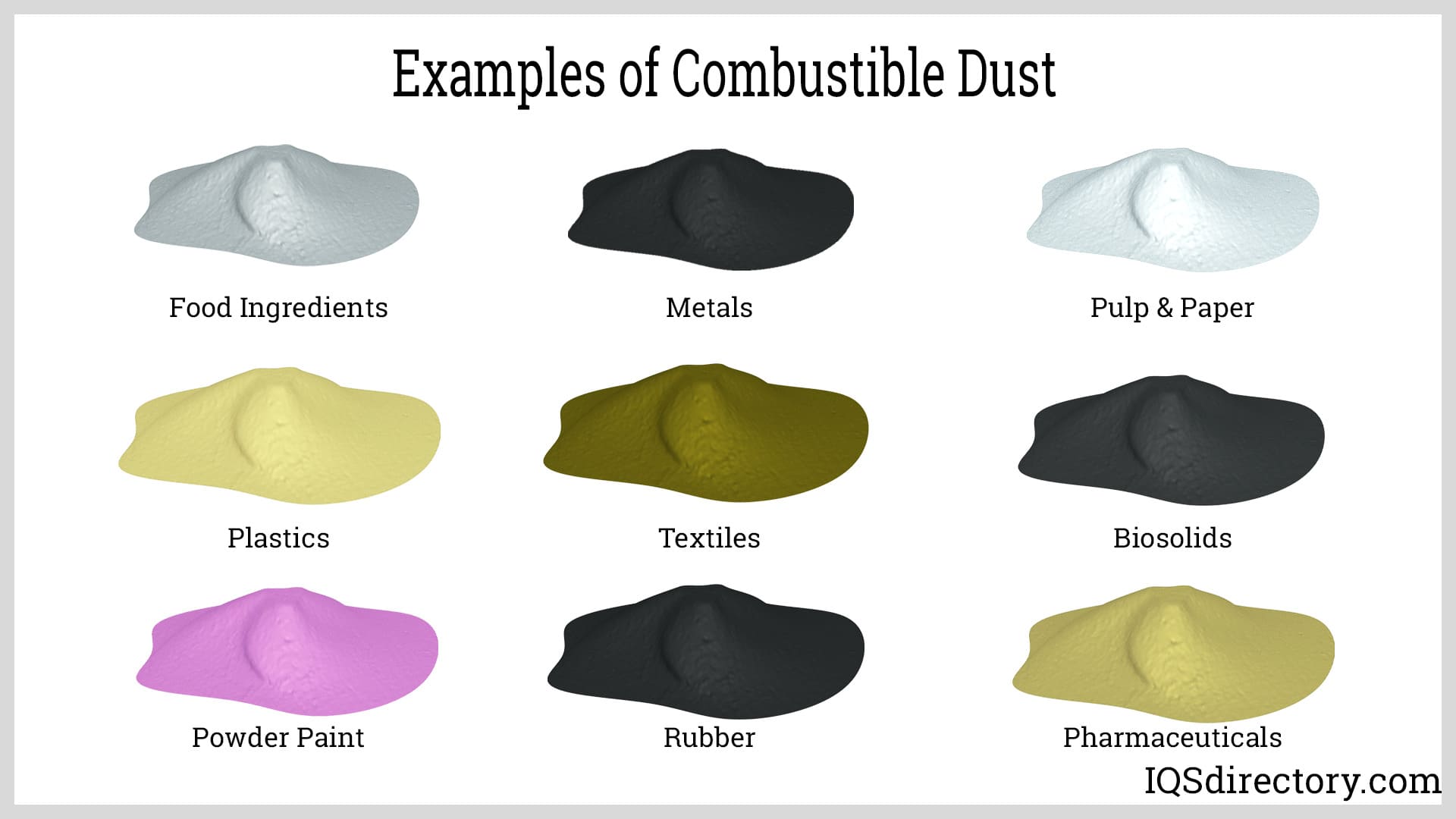

- Health and safety compliance: Cyclone dust collectors play a vital role in maintaining a safe workplace. By capturing hazardous dusts (e.g., silica, metal fumes, combustible dust), they help mitigate risks of respiratory illness, fire, and explosion, and support compliance with OSHA, NFPA, and EPA standards.

Frequently Asked Questions: Cyclone Dust Collectors

- How do I size a cyclone dust collector for my application?

Sizing depends on airflow (CFM), particle size distribution, dust loading rates, and the required separation efficiency. Consulting with a reputable manufacturer or using online calculators can help you estimate the optimal cyclone diameter and system configuration. - Can a cyclone dust collector replace a baghouse or cartridge collector?

Cyclones are most effective for larger, heavier particulates. For full-spectrum dust control, they are commonly used as a first-stage separator before more precise filtration like baghouses or cartridge collectors, which target finer airborne particles. - What maintenance does a cyclone dust collector require?

Cyclones are valued for low maintenance needs—primarily periodic emptying of collection hoppers and checking for wear or blockages. Unlike filter-based systems, there are no filter media to replace. - Are cyclone dust collectors suitable for combustible dust?

Yes, they can be used for combustible dust control, but must be properly designed with explosion vents and grounding per NFPA standards. Always consult with a dust collection specialist to ensure compliance.

Benefits of Cyclone Dust Collectors: Why Choose Cyclonic Separation?

Investing in a cyclone dust collector delivers several operational, economic, and environmental benefits for industrial and commercial facilities:

- Reduced filter maintenance and replacement costs: By capturing the bulk of dust before it reaches finer filters, cyclones extend filter life and decrease the frequency of filter change-outs and cleaning in baghouses and cartridge systems.

- Enhanced system reliability: With fewer moving parts, cyclone separators are less prone to mechanical failure, minimizing unexpected downtime and associated repair costs.

- Improved workplace health and safety: Effective dust extraction reduces airborne particulates that contribute to respiratory problems, allergies, and occupational illnesses, while also minimizing fire and explosion hazards.

- Energy efficiency: Cyclone dust collectors operate with lower pressure drops compared to filter-based systems, resulting in reduced energy consumption for air movement.

- Regulatory compliance: Cyclone systems help facilities meet stringent air quality and dust control regulations, supporting both environmental stewardship and legal compliance.

- Versatility and scalability: Suitable for standalone use or as part of multi-stage filtration setups, cyclone collectors can be customized for small shops or scaled for large industrial processes.

Comparing Cyclone Dust Collectors to Other Dust Collection Technologies

How do cyclone dust collectors compare with other dust collection systems? While baghouses, cartridge collectors, and electrostatic precipitators all play roles in industrial air filtration, cyclones offer unique strengths in specific scenarios:

- Cyclone vs. Baghouse: Cyclones handle large, abrasive particles and heavy dust loads with minimal maintenance, while baghouses excel at capturing fine particulate and hazardous dusts.

- Cyclone vs. Cartridge Collectors: Cartridge collectors provide high-efficiency filtration for fine dust, but are more sensitive to overloading and require more frequent maintenance than cyclones in high-dust environments.

- Cyclone vs. Wet Scrubbers: Wet scrubbers are used for sticky, moist, or hazardous dusts and fumes, but cyclones offer a dry, low-maintenance solution for bulk solid particulate removal.

Looking for advice on which dust collection system fits your needs? Explore our directory of dust collector manufacturers or request a quote from leading suppliers.

Decision Factors: What to Ask When Purchasing a Cyclone Dust Collector

Ready to buy a cyclone dust collector? Here are critical questions and decision factors to guide your purchase process:

- What is the maximum and average dust load (by weight and volume) in your process?

- What particle size range must be captured? Is the dust hazardous, abrasive, or combustible?

- What are your airflow and static pressure requirements?

- How much space is available for installation and future expansion?

- Will the system need to integrate with other dust control or air filtration equipment?

- What are your desired maintenance intervals and resource availability?

- Are there specific industry or regulatory compliance needs (OSHA, NFPA, EPA)?

- What is your budget, both for initial investment and long-term operation?

- Do you require custom engineering, special materials (e.g., stainless steel), or explosion protection features?

Consulting with an experienced dust collection system manufacturer ensures your cyclone dust collector meets all operational, safety, and regulatory needs.

Maintenance Best Practices for Cyclone Dust Collectors

To maximize the efficiency and lifespan of your cyclone dust collector, follow these maintenance best practices:

- Regularly inspect and empty the collection hopper to prevent blockages and overflow.

- Check for wear or corrosion on the cyclone body, especially in abrasive applications.

- Monitor system pressure drop and airflow to detect potential clogs or leaks.

- Ensure all gaskets and seals are intact to prevent dust bypass.

- Schedule periodic cleaning of downstream filters and check integration points with other dust control equipment.

Future Trends in Cyclone Dust Collection Technology

As industrial air quality standards become more stringent, cyclone dust collector technology continues to evolve. Recent advancements include:

- Enhanced aerodynamic design for improved separation efficiency and lower energy consumption.

- Integration with smart sensors and IoT systems for real-time monitoring of dust loads, airflow, and maintenance needs.

- Modular systems that allow for easy scaling and flexible installation in a variety of facility layouts.

- Hybrid dust collection solutions that combine cyclonic separation with HEPA filtration, activated carbon, or wet scrubbing for comprehensive air pollution control.

Are you interested in the latest innovations in dust collection and air filtration? Browse our resource center or connect with leading manufacturers for product demos and technical support.

Selecting the Best Cyclone Dust Collector Company

To ensure you achieve the best results when purchasing a cyclone dust collector, it’s important to evaluate several cyclone dust collector manufacturers. Our comprehensive directory allows you to compare business profiles highlighting each supplier’s experience, product range, and technical capabilities. Use our built-in website previewer to research each company’s specialties, and contact manufacturers directly for more information or to request a detailed quote.

- Review case studies and customer testimonials to gauge real-world performance.

- Ask about customization options, engineering support, and aftermarket service.

- Utilize our simple RFQ form to contact multiple cyclone dust collector companies with a single inquiry—streamlining your procurement process.

Ready to take the next step?

Start your search for the ideal cyclone dust collector manufacturer and explore solutions that will optimize your facility’s air quality, boost productivity, and protect your workforce.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services