Industrial dust collectors are air pollution control equipment used in manufacturing facilities, plants, warehouses, and other industrial or commercial environments to comply with environmental and worker safety regulations. Read More…

Scientific Dust Collectors (SDC) began in 1981 when our first patent for improving filter cleaning was issued. Since then, SDC has been issued a number of additional related patents for improvements in dust collector cleaning technologies including our patented nozzle-based cleaning system which is superior to other collectors. Combined with our High Side Inlets, Wide Filter Spacing, and Inlet...

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our dust collector systems. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

At Coral USA Innovative Air Solutions, we are committed to delivering high-performance dust collection systems that enhance workplace safety, improve air quality, and ensure compliance with industry regulations. With extensive experience in air filtration and dust control, we design and manufacture advanced dust collectors that effectively capture and remove airborne contaminants, providing...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. Eliminating airborne contamination in the workspace can lead to better employee performance and a lower rate of absenteeism.

More Industrial Dust Collector Manufacturers

Industrial Dust Collectors: Comprehensive Guide to Dust Collection Systems, Applications, and Buyer Considerations

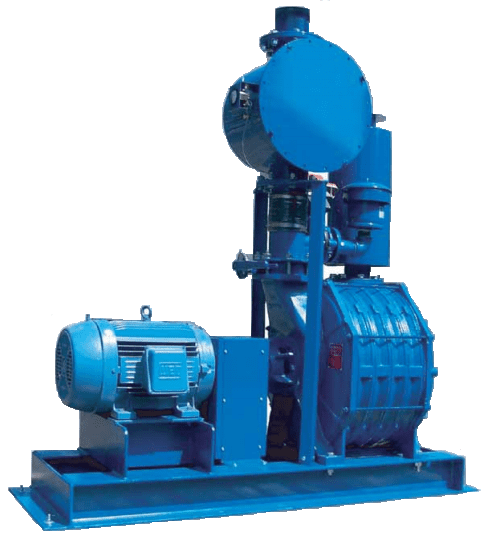

Efficient dust collecting systems play a vital role in modern production and manufacturing environments by managing, minimizing, and eliminating potentially hazardous particulate matter and fumes from gases. These advanced solutions are engineered to capture and filter airborne contaminants produced during industrial processes, thereby safeguarding both worker health and equipment performance while ensuring regulatory compliance. With the increasing focus on workplace safety, air quality, and environmental standards, understanding the diverse range of dust collection technologies and their real-world applications is crucial for facility managers, EHS (Environmental Health & Safety) professionals, and purchasing decision-makers.

The primary function of industrial dust collectors is to filter and purify dangerous dust and fine particle contaminant matter introduced into the workplace or atmosphere. This not only helps maintain and improve air quality, but also supports operational efficiency by minimizing equipment downtime and reducing the risk of fire or explosion due to combustible dust accumulation. As industries continue to adopt more stringent safety practices, investing in the right dust collection system is becoming an essential step in plant and facility management.

Types of Industrial Dust Collection Systems

Selecting the right industrial dust collection system depends on various factors, including the type and volume of dust generated, facility layout, air flow requirements, and compliance obligations. Below, we explore the most widely used dust collector types, their working principles, typical applications, and unique advantages.

Shaker Dust Collectors

Shaker dust collectors are a key component of shake-cleaning baghouse systems. In these systems, dust-laden air passes through filter bags that trap particulate matter. Periodically, the airflow is briefly halted, and the shaker mechanism vibrates or "shakes" the bags to dislodge the accumulated dust cake, which then falls into a hopper for disposal. The system can be designed for either offline cleaning (entire unit paused) or with compartmentalized sections that allow for continuous operation, taking individual compartments offline for cleaning or maintenance as needed.

These dust collectors are ideally suited for environments where supplying compressed air for cleaning is impractical, such as foundries, steel mills, mining operations, power plants, and smelting industries. Shaker baghouses are also commonly used in bulk storage silos and facilities handling dry commodities, where robust, low-maintenance dust filtration is essential.

- Key benefits: Simple design, lower maintenance, no need for compressed air, reliable operation in harsh environments.

- Common industries: Metal casting, mineral processing, grain storage, cement plants, and recycling facilities.

Electrostatic Precipitators (ESPs)

Electrostatic precipitators (ESPs) utilize static electricity to filter soot, ash, and fine dust particles from industrial exhaust gases. As contaminated air flows through an ionization chamber, high-voltage electrodes create an electric field that charges airborne particles. These charged particles are then attracted to oppositely charged collector plates, where they accumulate and are periodically removed. ESPs can capture submicron particulate (down to 0.01 microns), making them highly effective for fine particulate removal.

ESPs are widely implemented in power generation plants—especially coal-fired and oil-fired facilities—where the removal of fine fly ash, sulfuric acid mist, and other hazardous air pollutants is critical for meeting environmental standards such as the Clean Air Act. Additionally, electrostatic precipitators are used in cement kilns, pulp and paper mills, waste incinerators, and certain chemical manufacturing processes.

- Key benefits: High collection efficiency for very fine particles, minimal pressure drop, suitable for large air volumes.

- Common industries: Power generation, cement manufacturing, pulp and paper, chemical processing, waste-to-energy.

Pulse Jet Dust Collectors

The pulse jet dust collector is one of the most popular and versatile baghouse dust collection systems used across a wide range of industrial sectors. This design utilizes compressed air to clean the filter bags while the system remains in operation. Short bursts or "pulses" of high-pressure air are directed through the bags, flexing them and dislodging dust accumulation, which then falls into a collection bin. This enables continuous filtration without shutting down the process.

Pulse jet collectors are highly customizable and capable of handling various dust types, air flow rates, and temperature/pressure conditions. They are constructed from materials such as carbon steel, stainless steel, aluminum, Inconel, Hastelloy, and other specialty alloys, ensuring compatibility with corrosive, abrasive, or high-temperature applications. Their robust design and adaptability make them the preferred solution for industries handling bulk materials, including chemical processing, mineral extraction, food and beverage production, pharmaceuticals, and metal fabrication.

- Key benefits: Continuous operation, minimal downtime, high collection efficiency, wide material compatibility, compact footprint.

- Common industries: Food processing, pharmaceutical manufacturing, plastics, wood products, cement, chemical, and metalworking industries.

Cartridge Dust Collectors

Cartridge dust collectors are a type of cloth filter system engineered for applications requiring compact design, high efficiency, and easy maintenance. Instead of traditional filter bags, these systems use cylindrical or oval cartridges with pleated filter media, providing a large filtration area within a small space. Fewer filters and efficient design enable outside filter changes, reducing operator exposure to hazardous dust and minimizing labor costs.

Cartridge collectors excel in filtering fine, light-to-moderate dust loads, making them ideal for environments such as pharmaceutical manufacturing, powder coating, welding fume extraction, metalworking, woodworking, 3D printing, and thermal spray operations. Their versatility allows for integration with source-capture hoods, downdraft tables, and central dust collection networks.

- Key benefits: Space-saving design, easy filter replacement, lower maintenance, improved safety, high efficiency for fine particulate.

- Common industries and use cases: Electronics manufacturing, laser cutting, food processing, additive manufacturing, laboratory environments, and more.

Wet Scrubbers and Wet Dust Collectors

Wet dust collectors, including wet scrubbers, are essential for applications where dust is combustible, sticky, or hygroscopic (water-attracting). These systems use water or other liquids to capture dust particles from the air, preventing fire hazards and explosions associated with dry dust. Wet collectors are especially necessary for handling aluminum, magnesium, titanium, and other reactive metals.

Wet scrubbers are also effective for controlling fumes, vapors, and gases, in addition to particulate. They are commonly found in metal finishing, battery plants, foundries, and processes generating acid mists or toxic emissions.

- Key benefits: Explosion risk reduction, control of sticky or soluble dust, dual particulate and gas removal, suitable for high-moisture environments.

- Common industries: Metal finishing, aluminum and titanium processing, chemical manufacturing, wastewater treatment, and battery production.

Cyclone Dust Collectors

Cyclone dust collectors utilize centrifugal force to separate larger particles from the airstream before the air reaches final filtration stages. As air swirls inside a conical chamber, heavier dust particles are flung to the outer wall and drop into a collection bin, while cleaner air exits through the top. Cyclones are often used as pre-cleaners upstream of baghouses or cartridge collectors, extending filter life and improving overall system efficiency.

Cyclones are suitable for woodworking, grain processing, sawmills, and other applications where large, coarse dust is present.

- Key benefits: Low maintenance, no moving parts, effective pre-filtration, reduces filter loading and maintenance costs.

- Common applications: Woodshops, agricultural facilities, bulk material handling, cement plants.

Factors to Consider When Choosing an Industrial Dust Collector

When selecting a dust collection system for your facility, careful evaluation of your unique application requirements is essential. Here are the critical considerations to address:

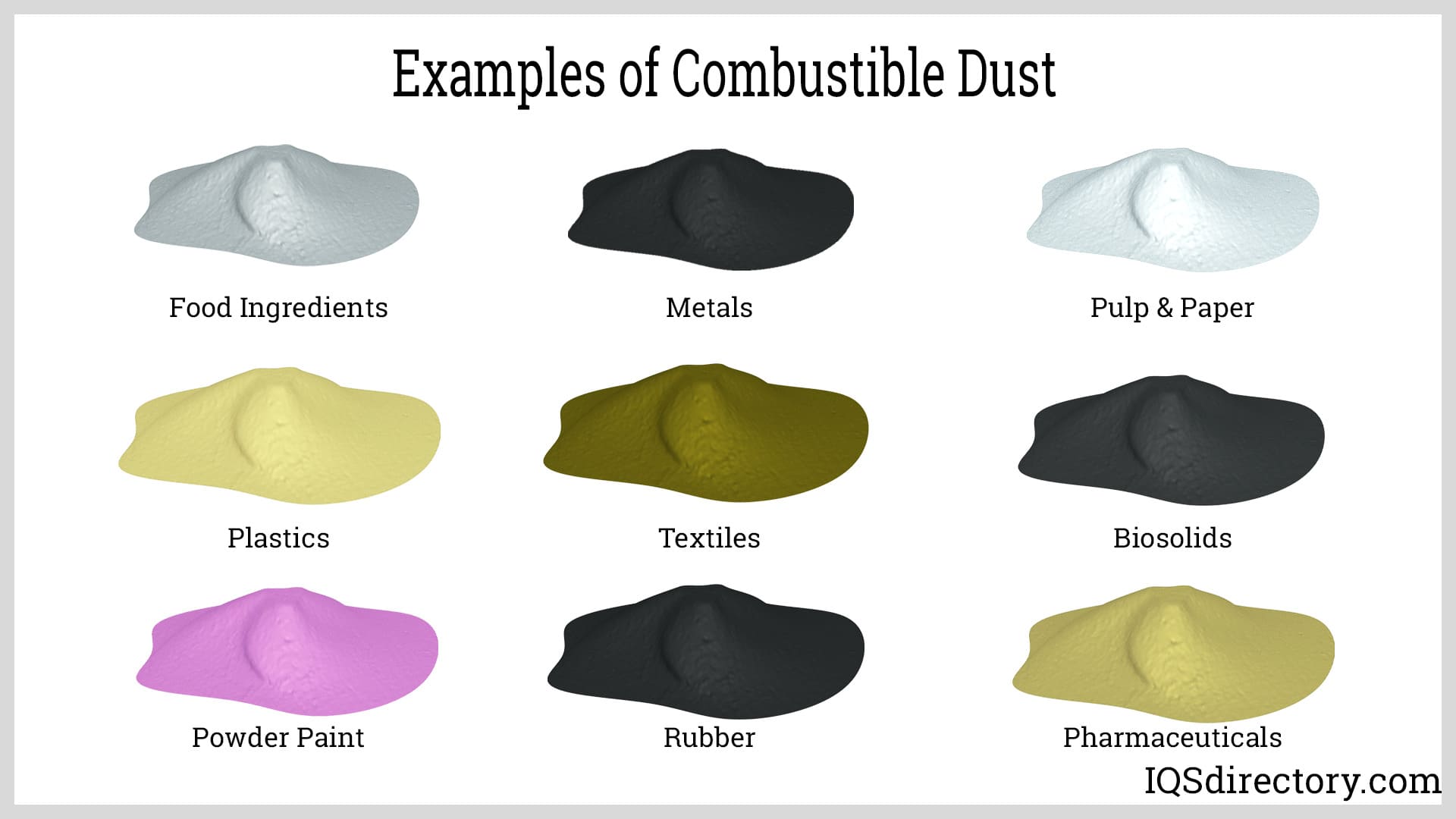

- Dust Characteristics: Determine the type (combustible, corrosive, sticky, hygroscopic, explosive), particle size (micron rating), and loading (concentration) of dust produced. Certain dusts—such as metal powders, food ingredients, or pharmaceutical compounds—may require special filtration media or system design for safe handling.

- Airflow and System Capacity: Calculate the required air volume (CFM) and static pressure to ensure effective dust capture at all emission points. Undersized systems can lead to poor air quality and regulatory violations.

- Industry Regulations and Compliance: Ensure your dust collector meets OSHA, NFPA, EPA, and local air quality codes, especially when handling combustible dusts or hazardous materials. Review requirements for explosion protection, spark detection, and emission limits.

- Operating Environment: Assess temperature, humidity, and corrosive conditions that may affect system performance or material selection (e.g., stainless steel for corrosive dusts, polypropylene for low-heat, chemical resistance).

- Space and Layout Constraints: Consider available floor space, ceiling height, and integration with existing equipment or ductwork. Compact systems like cartridge collectors may be preferable for space-limited facilities.

- Maintenance Requirements: Evaluate ease of filter replacement, hopper access, cleaning method (manual, shaker, pulse jet, wet), and downtime impact. Automated cleaning systems can reduce labor costs and improve safety.

- Operational Cost: Analyze total cost of ownership, including energy use, filter replacement frequency, and potential for dust recycling or recovery.

Are you unsure which industrial dust collection system is best for your application?

Start your search by asking:

- What type and volume of dust is generated by my process?

- Which industry standards or legal requirements apply to my facility?

- How much space is available for dust collector installation?

- Will I need explosion-proof or fire suppression features?

- What is my maintenance budget and staffing capability?

- Can any collected dust be recycled, reused, or sold?

Key Benefits of Industrial Dust Collection Systems

Investing in a well-designed industrial dust collector delivers numerous operational, financial, and safety advantages. Leading manufacturers offer integrated solutions that address diverse needs, from large-scale manufacturing plants to small fabrication shops. Here are some of the most significant benefits:

- Compliance and Risk Reduction: Dust collectors help facilities meet stringent air quality regulations (OSHA, NFPA, EPA), reducing the risk of fines, citations, or shutdowns. Explosion-vented and spark-resistant systems mitigate fire and explosion hazards.

- Enhanced Worker Health & Safety: By removing hazardous airborne particles, industrial dust collection systems protect workers from respiratory illnesses, skin irritation, and long-term health effects associated with exposure to silica, metal dust, allergens, and toxic compounds.

- Improved Product Quality: Clean air reduces the risk of product contamination and defects in sensitive manufacturing processes such as electronics, pharmaceuticals, and food production.

- Extended Equipment Life: Removing abrasive or corrosive dust prevents premature wear, overheating, or failure of motors, bearings, conveyors, and sensitive machinery, reducing repair and replacement costs.

- Increased Productivity: Automated dust collection improves workflow, reduces housekeeping needs, and minimizes process interruptions caused by dust accumulation or filter clogs.

- Resource Recovery and Sustainability: Some dust collectors enable the recovery of valuable materials (e.g., metal shavings, powders, or recyclable product), supporting waste minimization and circular economy initiatives.

- Soundproofing and Noise Control: Modern dust collectors can be equipped with acoustic enclosures or silencers to limit noise exposure, creating a more comfortable work environment.

Did you know? Many insurance providers offer premium discounts for facilities with certified dust collection and explosion protection equipment, recognizing their role in loss prevention and operational safety.

Industry Applications and Use Cases for Industrial Dust Collectors

Industrial dust collectors are indispensable across a wide spectrum of industries, each presenting unique air quality challenges and regulatory requirements. Explore the most common applications below to better understand where dust collection systems make a critical impact:

- Metalworking and Fabrication: Welding, grinding, plasma cutting, and machining operations generate fine metal dust, fumes, and sparks that require high-efficiency filtration and fire protection.

- Woodworking and Furniture Manufacturing: Sawmills, cabinet shops, and flooring plants rely on dust collectors to manage wood chips, sawdust, and fine particulates, protecting workers and preventing combustible dust hazards.

- Pharmaceutical and Chemical Processing: Cleanroom manufacturing, blending, and material handling produce hazardous and cross-contaminant dusts, demanding HEPA filtration and easy-to-clean designs.

- Food and Beverage Production: Dry ingredient handling, sugar and flour processing, and baking lines require dust collectors with food-grade, sanitary construction.

- Mining and Mineral Processing: Crushers, conveyor transfer points, bagging, and screening operations generate large volumes of respirable dust, necessitating robust and corrosion-resistant collection systems.

- Cement and Building Materials: Dust control is critical at kilns, silos, and mixing stations to prevent product loss, pollution, and equipment damage.

- Plastics and Composites Manufacturing: Pelleting, grinding, and molding processes create fine polymer dusts and fumes that must be efficiently captured.

- Pulp, Paper, and Printing: Paper dust, toner particulates, and ink mist are managed with advanced filtration to protect print quality and worker health.

- Recycling and Waste Management: Shredding, sorting, and material recovery facilities utilize dust collectors for air pollution control and compliance.

Curious how to optimize dust collection for your specific process?

Try searching for:

- "Best dust collector for welding fumes"

- "How to size an industrial dust collection system"

- "NFPA compliant dust collectors for woodshops"

- "Explosion-proof dust collector for aluminum dust"

- "Cartridge vs baghouse dust collector comparison"

How to Select the Right Industrial Dust Collector Manufacturer

Choosing the right industrial dust collector manufacturer is just as important as selecting the proper system type. Partnering with a reputable supplier ensures you receive application-specific engineering, quality components, and reliable aftermarket support.

- Experience and Expertise: Look for manufacturers with a proven track record in your industry, offering a range of system types (baghouse, cartridge, wet, cyclone, ESP) and customization options.

- Engineering Support: Leading suppliers provide site assessments, CAD design, air flow modeling, and compliance consulting to optimize system selection and installation.

- Certifications: Verify certifications for explosion protection (NFPA, ATEX), OSHA compliance, and filtration performance (HEPA, UL).

- Aftermarket Service: Reliable manufacturers offer filter replacements, maintenance plans, technical support, and troubleshooting.

- References and Reviews: Check customer testimonials, case studies, and independent reviews to gauge satisfaction and project success rates.

Looking for a trusted dust collector supplier?

Compare multiple companies using our directory of industrial dust collector manufacturers. Each business profile highlights their specialized experience, capabilities, and contact options. Use our patented website previewer for an in-depth look at each manufacturer's expertise, and our easy RFQ form to request pricing and proposals from several suppliers with a single submission.

Frequently Asked Questions About Industrial Dust Collection

What is the difference between a baghouse and a cartridge dust collector?

Baghouses use long, tubular filter bags and are preferred for high-volume, heavy dust loads. Cartridge collectors use pleated filters and are ideal for fine dust in compact spaces.

How often should I replace my dust collector filters?

Filter replacement frequency depends on dust type, loading, and operating hours. Many systems have pressure drop monitors to indicate when filters need changing; always follow manufacturer recommendations.

Can dust collectors be used for combustible dust?

Yes, but the system must be designed for explosion protection (venting, suppression, grounding) and comply with NFPA standards for combustible dust control.

How do I calculate the proper size for my dust collection system?

Calculate required air volume (CFM), static pressure, and ductwork layout. Consult with your manufacturer or use online sizing calculators for guidance.

What maintenance is required for industrial dust collectors?

Typical maintenance includes filter inspection and replacement, hopper emptying, cleaning mechanisms check, and periodic system performance audits. Automated cleaning systems reduce manual maintenance.

Start Your Dust Collection Project Today

Whether upgrading an existing system or designing a new facility, investing in the right dust collection equipment is essential for worker health, compliance, and operational efficiency. Begin by identifying your dust control needs, researching system types, and comparing manufacturers. For expert guidance and competitive quotes, use our comprehensive industrial dust collector manufacturer directory and RFQ tool to connect with leading suppliers.

Ready to enhance your facility’s air quality and safety?

Explore our resource center for more guides, case studies, and product comparisons on industrial dust collection, air pollution control, and workplace safety solutions.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services