Although wet collectors are frequently employed in machining, they can also be used in other industries like food processing, pharmaceuticals, and biomedical manufacturing. Wet dust collectors force air through a body of water to capture dust and other particles. To capture moisture droplets that the airstream might carry out of the collector, the system is designed to drive airflow down towards the water, through impingers or a water spray, and then up through additional metal filtration. This device effectively removes airborne contaminants that could be dangerous if improperly contained. Read More…

Scientific Dust Collectors (SDC) began in 1981 when our first patent for improving filter cleaning was issued. Since then, SDC has been issued a number of additional related patents for improvements in dust collector cleaning technologies including our patented nozzle-based cleaning system which is superior to other collectors. Combined with our High Side Inlets, Wide Filter Spacing, and Inlet...

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our dust collector systems. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

At Coral USA Innovative Air Solutions, we are committed to delivering high-performance dust collection systems that enhance workplace safety, improve air quality, and ensure compliance with industry regulations. With extensive experience in air filtration and dust control, we design and manufacture advanced dust collectors that effectively capture and remove airborne contaminants, providing...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. Eliminating airborne contamination in the workspace can lead to better employee performance and a lower rate of absenteeism.

More Wet Dust Collector Manufacturers

Comprehensive Guide to Wet Dust Collectors: Design, Benefits, Applications & Selection

Introduction to Wet Dust Collectors

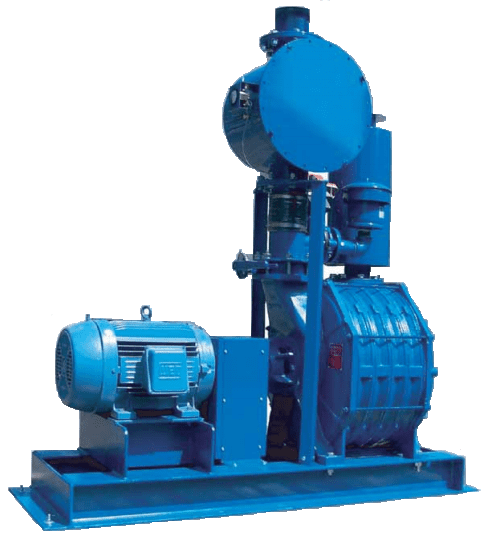

Wet dust collectors, also known as wet scrubbers or wet collection systems, are specialized air pollution control devices designed to remove dust particles, fumes, and hazardous contaminants from industrial exhaust streams. Unlike dry filtration systems such as baghouses or cartridge dust collectors, wet dust collectors use water or other liquids to capture and neutralize airborne particulates. These systems are essential in industries where dust is sticky, explosive, corrosive, or contains metallic or combustible particles. If you're researching industrial dust control solutions, understanding the advantages and limitations of wet dust collectors is crucial for workplace safety and regulatory compliance.

Design of Wet Dust Collectors

The engineering behind wet dust collection systems is grounded in three fundamental design configurations: gas-humidification, gas-liquid contact, and gas-liquid separation. Each approach addresses specific particulate characteristics and industry requirements. Let’s break down the core processes:

- Gas-Humidification: This stage increases the moisture content of the airstream, promoting particle agglomeration and making fine particles easier to capture.

- Gas-Liquid Contact: Through mechanisms like inertial impaction, interception, diffusion, or condensation nucleation, dust-laden air is intimately mixed with water droplets. This interaction causes dust particles to adhere to the liquid, effectively removing them from the airflow.

- Gas-Liquid Separation: After particle capture, the cleaned or “scrubbed” gasses pass through a demister, which removes excess water droplets, ensuring only clean air is released.

The contaminated water, now carrying the captured dust, is either treated on-site or recycled back into the dust collector system. To manage the solid waste, a clarity unit or drag tank chain removes the settled dust and sludge, depositing it into bins or stockpiles for proper disposal.

Types of Wet Dust Collectors

There are several types of wet dust collection equipment tailored to specific applications and dust characteristics. The most common include:

- Gravity-Spray-Power Scrubbers: These low-energy wet dust collectors use spray nozzles to atomize water, forming droplets that fall through rising exhaust fumes. They are effective for larger particles but tend to be around 70% efficient for particles smaller than 10 μm and less effective below this size. Their main advantage is resistance to clogging, even when handling sticky or high-concentration dust streams.

- Wet Cyclones: Wet cyclone collectors use centrifugal force to spin dust particles against wetted walls. Water injected from the top washes particles away. This design is ideal for handling abrasive or corrosive dust and is generally effective for particles 5 μm or larger. Wet cyclones can be configured as stand-alone units or as a pre-filtering stage in multi-step dust collection systems.

- Venturi Scrubbers: These high-efficiency systems accelerate the dust-laden air through a constriction (venturi throat), creating intense mixing with injected water. The resulting turbulence maximizes particle capture, making venturi scrubbers suitable for submicron dust and hazardous fumes. They are common in chemical processing, metal finishing, and pharmaceutical dust collection applications.

- Packed Bed Scrubbers: Used where chemical absorption is also required (such as acid gas removal), packed bed scrubbers force air through a bed of wetted packing media. This increases contact surface area for dust and vapor-phase contaminant removal.

Did you know? Many industrial facilities combine multiple wet dust collection technologies to achieve optimal filtration efficiency and meet strict air quality standards.

Key Considerations When Choosing Wet Dust Collectors

Selecting the right wet dust collector for your facility involves evaluating several critical factors. Making an informed decision can mean the difference between regulatory compliance, operational efficiency, and costly downtime. Here are some of the most important aspects to consider:

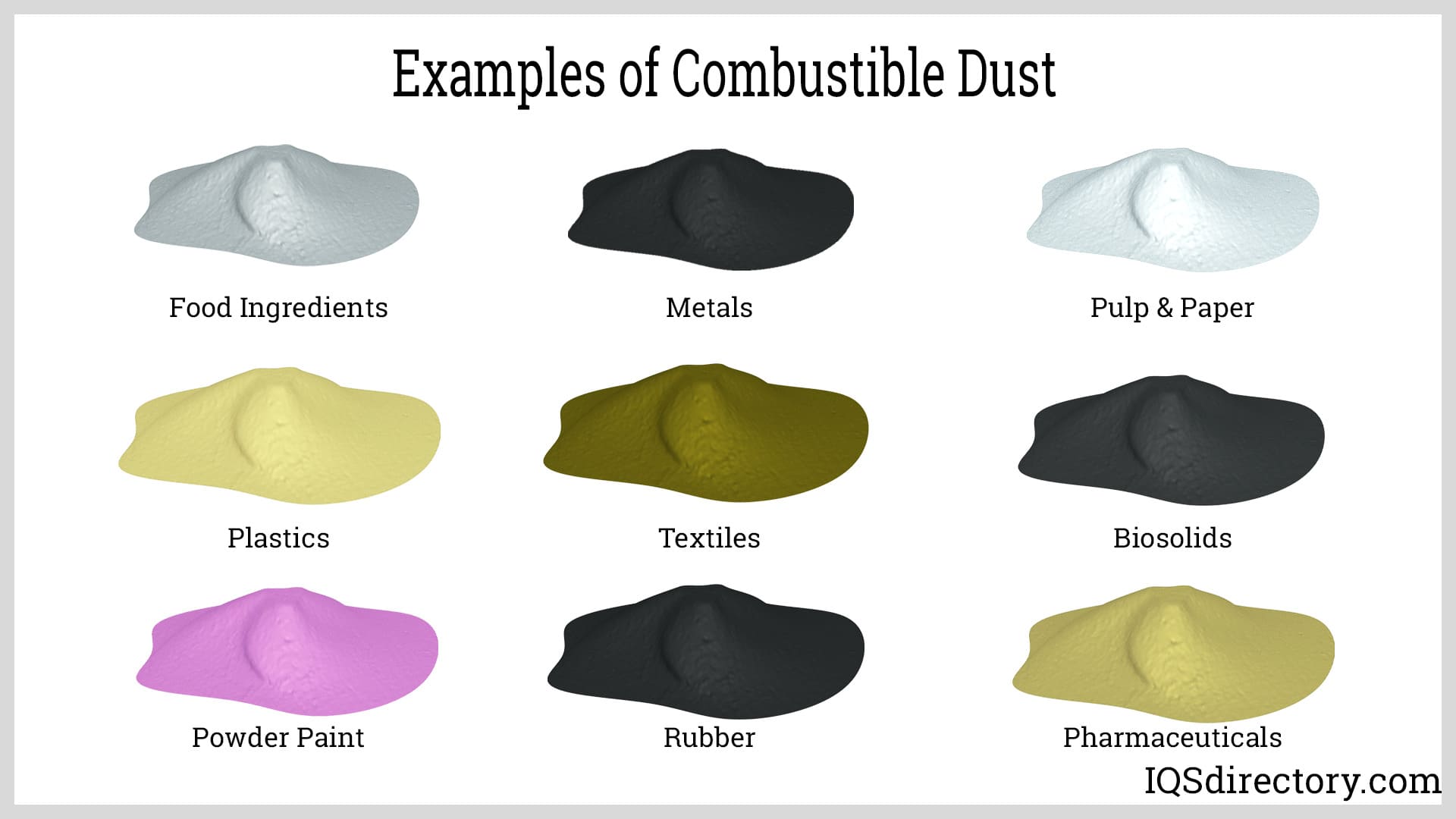

- Type of Dust: Is the dust generated in your process sticky, hygroscopic, combustible, or metallic? These characteristics influence the potential for clogging and the effectiveness of wet collection. For example, wet dust collectors excel in applications where baghouse dust collectors would quickly clog, such as in pharmaceutical, food processing, or metalworking environments.

- Dust Particle Size, Shape, and Hazard: Are you dealing with fine particulates, ragged edges, or fibrous materials? Metal fines and abrasive dusts can damage fabric filters in dry collectors, but wet systems can handle these without excessive wear. If your process generates ultrafine or hazardous dust, ask: What level of particulate filtration is required for compliance?

- Chemical Corrosiveness: Does your dust stream contain corrosive agents, acids, or alkalis? In such cases, stainless steel, FRP (fiberglass reinforced plastic), or polypropylene dust collectors are preferred to ensure long system life and performance.

- Temperature and Humidity: High temperature or variable humidity can affect both dust characteristics and collector materials. Wet dust collectors can be engineered for temperature resistance, but material selection is critical.

- Airflow and Volume: What is your required air volume (CFM)? Industrial wet dust collectors can handle a wide range of airflows, from small bench-top units to massive centralized systems for entire manufacturing plants.

- Regulatory Compliance: Are you subject to OSHA, NFPA, EPA, or local air quality regulations? Wet collection systems are often chosen for combustible dust applications because they reduce explosion risks and help meet safety standards.

- Maintenance and Disposal: Consider the ease of system maintenance, water treatment requirements, and disposal of collected sludge. Ask yourself: How will ongoing maintenance impact operating costs and uptime?

- Energy Consumption: Wet dust collectors may use more energy than dry units due to water recirculation and pumping. However, this can be offset by reduced filter replacement and downtime.

Industry Applications for Wet Dust Collectors

Wet dust collection systems are widely used across industries where dry filtration is impractical or unsafe. Common applications include:

- Metalworking and Foundries: Grinding, polishing, and welding generate metal fines and sparks, making wet dust collectors ideal for fire and explosion prevention.

- Food Processing: Sticky, hygroscopic, or combustible dusts from sugar, flour, or spices are efficiently controlled with wet scrubbers.

- Chemical and Pharmaceutical Manufacturing: Handling hazardous, corrosive, or reactive dusts requires robust wet collection solutions with chemical-resistant construction.

- Woodworking and Furniture Manufacturing: Sawdust, wood fibers, and fine particulates are controlled to improve air quality and minimize fire hazards.

- Battery and Electronics Production: Toxic particulates such as lead or cadmium dust are safely captured and neutralized.

- Recycling Facilities: Shredding and sorting processes generate airborne contaminants that must be controlled for worker safety and environmental compliance.

Benefits of Wet Dust Collection Systems

Investing in a wet dust collector delivers a range of operational, safety, and regulatory advantages. Here’s why businesses across industries are choosing wet collection technology:

- Suppression of Fire and Explosion Risks: Wet dust collectors dramatically reduce the potential for fire and dust explosions by using water to neutralize sparks and prevent dust accumulation. For environments where combustible dust is present (such as metalworking, woodworking, or grain handling), a wet system with integrated spark arrestors and explosion-proof design is often required by the NFPA and other safety organizations.

- Improved Air Quality and Odor Control: Wet scrubbers continuously circulate and filter workplace air, removing airborne particulates and odorous contaminants. This results in a healthier, more comfortable environment for employees and eliminates odors caused by biological or chemical processes. For industries where odor is a concern, carbon-impregnated filters can be added for additional filtration.

- Enhanced Regulatory Compliance: Agencies like OSHA, NIOSH, and the EPA set strict limits on airborne dust and contaminants. Wet dust collectors help companies meet these standards, avoid fines, and maintain operational permits.

- Worker Health and Safety: By reducing airborne dust, fumes, and toxic particles, wet dust collectors protect employee respiratory health and minimize the risk of occupational diseases. Facilities with robust dust control solutions report fewer health complaints and increased productivity.

- Lower Maintenance and Operating Costs: Wet dust collectors generally require less frequent filter replacement compared to dry systems. With fewer filter-related shutdowns, maintenance costs and system downtime are reduced.

- Versatility for Challenging Dusts: Wet collection is suitable for handling sticky, fibrous, corrosive, or high-moisture dusts that would quickly clog or damage traditional dry collectors.

- Flexible Integration: These systems can be designed as stand-alone solutions or integrated with existing ventilation, air pollution control, or dust extraction systems.

Comparing Wet Dust Collectors to Other Dust Collection Technologies

When evaluating wet dust collectors versus other dust extraction equipment such as baghouses, cartridge collectors, or electrostatic precipitators, it’s important to understand application-specific tradeoffs. Here’s a high-level comparison:

- Baghouse Dust Collectors: Highly effective for dry, non-sticky particulate matter and high airflows. Not suitable for sticky, corrosive, or combustible dusts, which can cause filter clogging or fire hazards.

- Cartridge Dust Collectors: Excellent for fine and light dusts but are prone to clogging with fibrous or moist particles.

- Electrostatic Precipitators: Effective for submicron particles in power generation or process industries, but not ideal for sticky or wet dusts.

- Wet Dust Collectors: The best choice for explosive, sticky, corrosive, or metallic dusts and for applications where fire or explosion risk is high. They also provide effective odor and gas scrubbing capabilities.

Curious how wet dust collectors stack up for your specific application? Explore our dust collection equipment directory or contact a specialist for a tailored recommendation.

How to Choose the Right Wet Dust Collector Company

Selecting a reputable wet dust collector supplier is a critical step in ensuring system performance, code compliance, and long-term ROI. Here’s a step-by-step guide:

- Research and Compare Suppliers: Use our wet dust collector manufacturer directory to find established suppliers with proven track records in your industry.

- Review Company Capabilities: Examine each supplier’s business profile to assess their experience with your specific dust types, airflow requirements, and regulatory challenges.

- Request Quotes and Technical Proposals: Use our simple RFQ form to contact multiple companies. Provide detailed information about your dust characteristics, process conditions, and compliance requirements for the most accurate proposals.

- Evaluate After-Sales Support: Inquire about maintenance services, spare parts availability, and technical support. Strong after-sales service can significantly reduce downtime and operating costs.

- Ask for Case Studies and References: Reputable suppliers should be able to provide customer testimonials and installation case studies demonstrating successful projects similar to yours.

- Check for Compliance and Certifications: Ensure the supplier’s products meet relevant industry standards, such as NFPA, OSHA, and EPA requirements.

Ready to take the next step? Contact leading wet dust collector suppliers today for tailored recommendations and detailed project quotes.

Frequently Asked Questions About Wet Dust Collectors

- What is the maintenance requirement for a wet dust collector? Maintenance typically involves regular inspection and cleaning of spray nozzles, pumps, demisters, and water treatment systems. Many systems offer automated self-cleaning features for reduced manual intervention.

- Are wet dust collectors suitable for combustible dust? Yes. Wet dust collectors are often the preferred solution for combustible dust because they neutralize ignition sources and prevent dust cloud formation, reducing explosion risk.

- How do I know if my process needs a wet or dry dust collector? Factors include dust characteristics (stickiness, combustibility, corrosiveness), regulatory requirements, and facility layout. Contact a dust collection expert for a professional assessment.

- Can wet dust collectors handle fumes and gases as well as dust? Many wet collectors, especially venturi and packed bed designs, are engineered to remove both particulate and gas-phase contaminants.

- What industries benefit most from wet dust collection? Metalworking, food processing, chemical manufacturing, recycling, and battery production are top candidates due to the nature and hazards of their dust streams.

- Are there environmental considerations? Yes. Collected water must be treated to remove contaminants before disposal or reuse. Many systems include integrated wastewater treatment options.

Next Steps: Selecting and Installing Your Wet Dust Collection System

Installing a wet dust collector is a significant investment in workplace safety, environmental compliance, and operational efficiency. Here’s how to move forward:

- Assess Your Dust Control Needs: Document dust sources, particle sizes, airflows, and compliance requirements.

- Consult with Industry Experts: Engage with specialist suppliers to discuss your application and receive recommendations.

- Request On-Site Evaluation: Many suppliers offer site visits to evaluate your facility and recommend system sizing, layout, and integration strategies.

- Plan for Installation and Commissioning: Scheduling installation during planned shutdowns minimizes disruption. Ensure staff is trained in system operation and basic maintenance.

- Monitor and Maintain: Regularly inspect and maintain your wet dust collector to ensure optimal performance and compliance.

Conclusion: Why Wet Dust Collectors Remain Essential in Modern Industry

As industrial processes become more complex and regulatory scrutiny increases, investing in the right dust collection technology is more important than ever. Wet dust collectors provide unmatched safety, versatility, and efficiency for controlling challenging dusts that would overwhelm traditional dry filtration systems. Whether you’re managing explosive metal fines, sticky food ingredients, or corrosive chemical particulates, a well-designed wet dust collection system can protect your workforce, maintain regulatory compliance, and safeguard your bottom line.

Start your journey towards safer, cleaner air today. Use our directory to request quotes from top wet dust collector manufacturers or contact us for expert guidance on your next project.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services